Blog

2026 Top Ball Screw for Sale Options and Tips for Buyers?

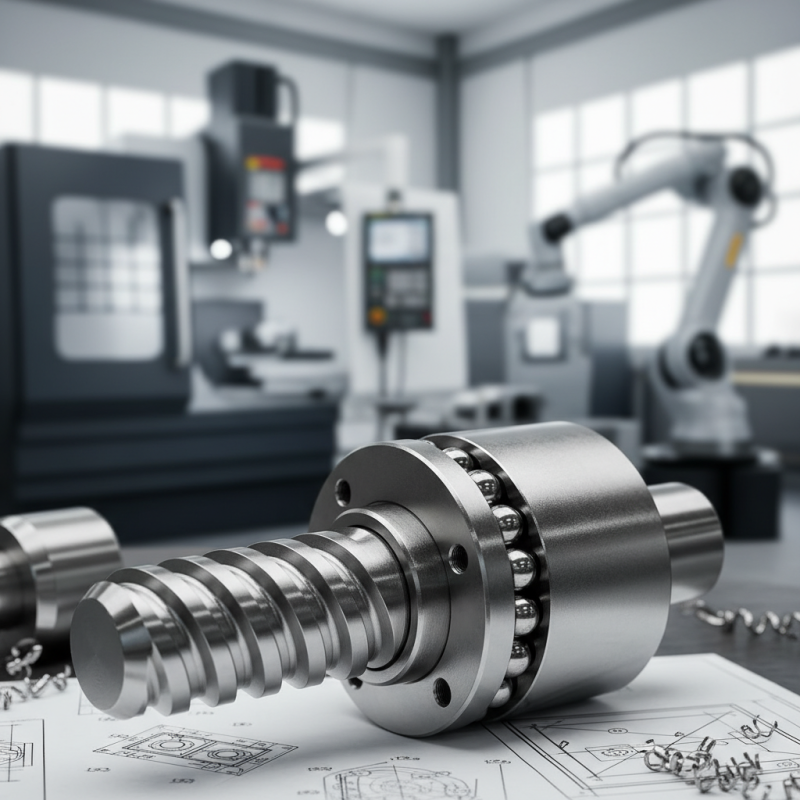

As the demand for precision machinery grows, ball screw for sale options are becoming increasingly vital. These components play a crucial role in converting rotary motion into linear motion with exceptional accuracy. When exploring the market, potential buyers often face an overwhelming array of choices. Understanding the specifics can help you find the right ball screw for your needs.

Searching for the best ball screw for sale requires careful consideration. Different manufacturers offer varying quality and performance levels. Some may boast advanced technology, but can they deliver? Pay attention to the details such as load capacity and durability. It's easy to get distracted by flashy marketing, but true quality lies beneath.

Buyers should also be aware of the pitfalls in their selection process. There's a fine line between cost-effectiveness and compromising quality. Opting for a cheaper option may save money upfront but could lead to greater expenses in the long run. Reflect on the importance of investing in reliable components. By doing so, you ensure better efficiency and longevity in your machinery.

2026 Ball Screw Market Overview and Growth Projections

The ball screw market is set for significant growth by 2026. Demand for precision machinery drives this trend. Industries like automotive and aerospace are key players. New technologies improve efficiency and reduce costs. This creates more opportunities for innovation and investment in ball screw systems.

When considering a ball screw, it’s crucial to evaluate specific needs. Not all screws are created equal. Assess load capacity and speed requirements carefully. Look for solutions that offer smooth operation and longevity. The quality of materials can greatly impact performance.

Invest time in research. Understand the material and design options. Seek advice from experts if needed. Engage with knowledgeable suppliers who can clarify technical details. This will aid in making a well-informed decision. Being precise in your specifications can lead to better outcomes, while vague choices may result in challenges later on.

Key Features and Specifications to Consider When Buying Ball Screws

When purchasing a ball screw, it’s essential to pay attention to key features. Load capacity is crucial. It dictates how much weight the screw can handle. Ensure it aligns with your project requirements. Also, consider the screw's length and diameter. These dimensions affect both performance and fit. A mismatch can lead to inefficiencies.

Bearings are another vital aspect. They determine the screw's efficiency and lifespan. Look for options that suit your operational speed and precision needs. The material of the ball screw can significantly influence performance too. Stainless steel offers durability, while alloy steel can provide higher strength.

Additionally, don't overlook lead accuracy. It directly impacts movement precision. If a screw is too imprecise, it can result in machining errors. Evaluate your application to identify acceptable tolerances. Overall, the right choice can enhance productivity. However, always leave room for adjustments and improvements later. Finding the perfect screw may take time and experimentation.

Top Manufacturers and Brands of Ball Screws in 2026

In 2026, the ball screw market emphasizes the importance of choosing reliable manufacturers. Quality ball screws enhance precision in machinery, impacting production efficiency. Leading industry reports indicate that the demand for high-performance ball screws has grown by over 15% annually, a trend projected to continue.

Several manufacturers stand out for their innovation and reliability. They prioritize materials and precision manufacturing processes. These brands often focus on providing enhanced torque capacities and longer service life. Data suggests that users experience a significant reduction in maintenance costs when selecting top-tier options.

Tips for buyers include evaluating the manufacturer's reputation through online reviews. Don’t overlook the specifications that matter. Pay attention to load capacity and accuracy. Sometimes, lower-priced options can lead to higher costs due to failures. Consider conducting a hands-on evaluation when possible.

The right choice today prevents regrets tomorrow.

Comparative Analysis of Pricing Trends for Ball Screws in 2026

In 2026, the ball screw market is witnessing notable pricing trends. Various reports indicate that the average price of ball screws has increased by approximately 12% compared to 2025. This rise is primarily attributed to increased raw material costs and supply chain disruptions. For buyers, understanding these factors is essential when making purchasing decisions.

Research shows that premium ball screws now range from $80 to $150 each, while more affordable options sit closer to $40 to $70. Buyers must be aware of the performance differences. It may seem tempting to choose lower-priced options, but this could lead to long-term inefficiencies. Quality should not be compromised for cost.

Tip 1: Always evaluate technical specifications before purchasing. Seek a balance between cost and quality.

Tip 2: Consider ordering in bulk. This often provides significant savings. Reflect on your actual needs to avoid unnecessary expenditures. Investing wisely today can mean greater efficiency and savings in the long run.

Tips for Ensuring Quality and Reliability in Ball Screw Purchases

When purchasing ball screws, quality and reliability are paramount. It's crucial to examine the specifications carefully. Look for details such as the lead accuracy and preload. Understanding these factors can prevent future issues. You might encounter options with varying tolerances. Consider how these differences affect performance in real applications.

It’s wise to check the manufacturer’s reputation. Reviews and testimonials can provide insight. However, beware of overly positive feedback. Sometimes, it may be misleading. Engaging with previous buyers directly can lead to realistic expectations. Ask about their experiences, and listen to both successes and failures.

Visual inspection is essential. Look for signs of wear or damage on the ball screw. Ensure that the finish is smooth and free of rust. This can often indicate the level of care in manufacturing. If possible, request a sample. Testing before committing can save resources and time. Make sure to reflect on your choices throughout this process.

2026 Top Ball Screw for Sale Options and Tips for Buyers

| Ball Screw Type | Diameter (mm) | Lead (mm) | Material | Accuracy Grade | Application | Price ($) | Supplier Rating |

|---|---|---|---|---|---|---|---|

| C5 High Precision | 16 | 5 | Alloy Steel | C5 | Robotics | 150 | 4.8/5 |

| C7 Standard | 20 | 10 | Carbon Steel | C7 | CNC Machines | 120 | 4.5/5 |

| C3 High Load | 25 | 8 | Stainless Steel | C3 | Industrial Automation | 200 | 4.7/5 |

| B7 Compact | 12 | 4 | Aluminum | B7 | Packaging Machinery | 80 | 4.6/5 |

| C6 Heavy Duty | 30 | 12 | High Carbon Steel | C6 | Construction Equipment | 250 | 4.9/5 |

Article Source:

About Us

We serve the Greater Milwaukee area: Waukesha, Milwaukee, Washington, Ozaukee Counties and nearby areas, including Germantown, Menomonee Falls, Mequon, Cedarburg, Thiensville, Grafton, Jackson, West Bend, Hartland, Waukesha, Brookfield, West Allis, Franklin, Greenfield and more. We are Wisconsin’s Best Contractor for Replacement Windows, Doors, Siding & Roofing!

Contact Details

Address:

N112 W14880 Mequon Road

Germantown, Wisconsin 53022

Phone:

Email:

Showroom Hours

Monday: 9am – 5pm

Tuesday: 9am – 5pm

Wednesday: 9am – 5pm

Thursday: 9am – 5pm

Friday: 9am – 4:30 pm

Saturday by Appointment

Evenings by Appointment